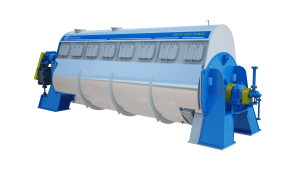

The Steam Rotate Dryer performs continuous drying through an indirect drying system, where the product comes into contact with a shaft with a large thermal exchange area, that shaft is heated by the injection of steam inside it, equipped with a set of strategically positioned tubes for greater heat transfer and process control.

The drying control is carried out through temperature sensors installed in specific points along the dryer body and in the entry and exit product control, increasing or decreasing the time inside the dryer, as well as the adjustment of steam pressure in the dryer shaft.

The drying process consists in the product reception that is conditioned inside the hopper, through a transporter is transferred from the hopper to the dryer, where the thermal exchange and the water evaporation take place; the dry mass is discharged through an extraction conveyor.

Drying systems are designed and developed for various types of products, including:

Indirect drying, guaranteeing product properties and no contamination

Low consumption of electrical energy

Optimized thermal transfer

Possibility of recovering thermal energy from drying gases

Totally controlled system via PLC and supervisor, guaranteeing total control of the process

Rendering or residues from

effluent treatment

High quality dry flour

Waste/dry sludge for boiler and

burning, composting or fertilizer